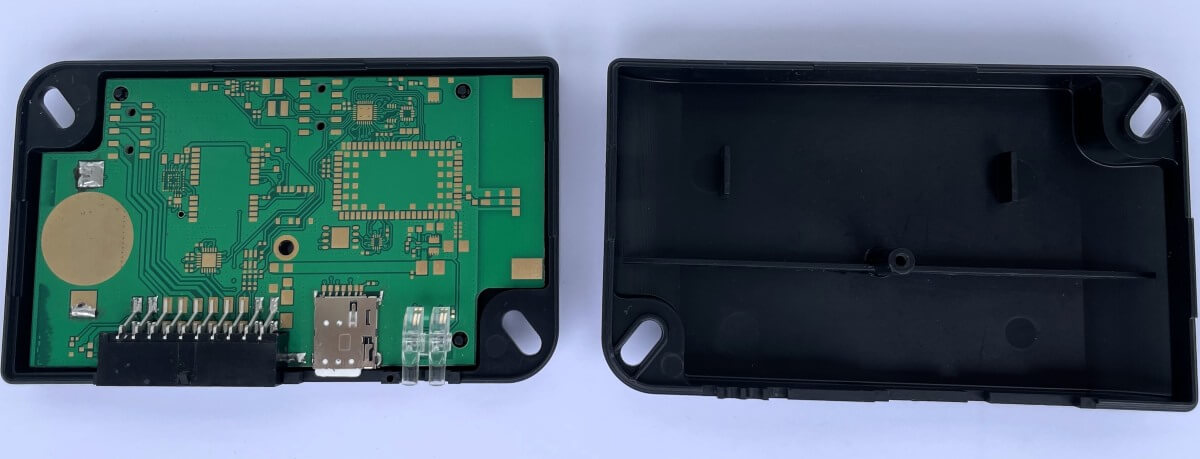

A customer approached us after being recommended by another customer, with challenges related to the responsiveness of their supplier for the repair of existing tools and the manufacturing of PCB cases. The PCB had been updated, which required urgent changes to the case. In addition, a problem had arisen with closing the case when the PCB was inserted.

We received the customer's existing tools and data used to manufacture the case. At a meeting with the customer, we proposed manufacturing the case from a self-extinguishing material that would meet the product specifications.

Our expert team carefully examined the existing case and PCB. We found that the problem with closing could be solved by making a simple change to the tool, which would maintain the high quality of the product.

In seven days, we created an accurate 3D model of the new insert in the tool based on the previous 3D model of the PCB. Speed and accuracy were key in this process.

The customer's quick decision was the next milestone in the process. They decided to manufacture the products from both materials - standard and self-extinguishing.

On day 14, we carried out the necessary upgrades to the tool for improved closure of the case and simultaneously manufactured the new insert. This quick response allowed the customer to avoid wasting valuable time.

Thorough testing of samples took place from day 15 to 16, ensuring the flawlessness and usability of the new product. This quick action allowed the customer to obtain a flawless product.

The customer was satisfied with the samples and immediately ordered the first series of cases, both from standard and self-extinguishing material.

We collected and archived all technical documentation in just 19 days, along with documentation on tool repairs and new inserts.

On day 21, we injection-molded the first series of cases from standard material, followed by the first series of cases from self-extinguishing material. We carefully packaged both series and prepared measurement reports. The products were ready for transport on day 23.

In just 25 days from the start of the challenge, we delivered the ordered cases. In addition, we presented the customer with the option of laser engraving/printing on the case, which replaced the previous tampoprint process.

This is an example of how MedicalPlast MD can quickly, reliably, and cost-effectively provide solutions for your needs. Our commitment to quality and our ability to continuously improve allows us to achieve the highest standards, regardless of the challenges we face.

If you are also in a situation where you need a quick and reliable solution, please contact us. We look forward to working with you and finding solutions to your challenges.